Sunraysia Water Efficiency Project (SWEP)

Creating a more efficient water delivery network across the Mildura, Red Cliffs and Merbein irrigation districts.

Creating a more efficient water delivery network across the Mildura, Red Cliffs and Merbein irrigation districts.

Modernising Sunraysia’s irrigation

The $37.9 million Sunraysia Water Efficiency Project (SWEP), delivered by Lower Murray Water (LMW) and funded by the Australian Government, improved irrigation efficiency across the Merbein, Mildura, and Red Cliffs Irrigation Districts.

Completed on time and within, the project included installing pipelines, lining channels, replacing flowmeters, and removing redundant assets. By minimising water leakage and seepage across Sunraysia’s irrigation network, once audited, the project will provide 1.8 GL annually of recovered water to the environment.

SWEP significantly contributed to LMW’s vision of continuing to provide an economically sustainable means of supplying irrigation water to support agribusiness throughout Sunraysia.

Project at a glance

-

Download

Download the SWEP completion report • PDF – 32.79mb

The channel challenge

Sunraysia’s water is delivered via a complex network of concrete and earthen channels, many of which were built over a century ago.

LMW had several challenges in maintaining this infrastructure, including:

- Difficulty in accessing the channels to respond to incidents, slowing response times.

- The threat of reduced agricultural productivity

- Inefficient water delivery systems due to ageing assets

- An increased risk of supply failure

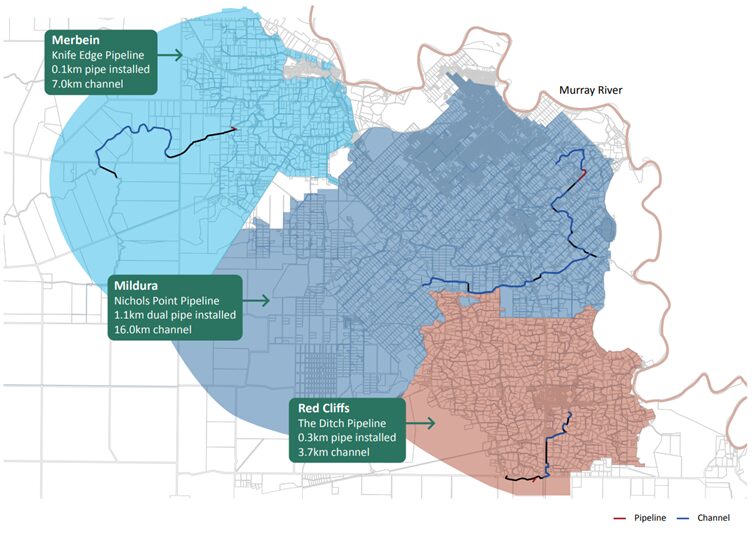

Project scope

The project had two main scope components:

1. Channels

The project aimed to modernise over 27 km of earthen and concrete channels across the network.

Earthen channels—unlined waterways carved into soil—posed risks due to slope collapses and suffered significant water seepage. Concrete channels faced heavy degradation, leading to water loss, leakage, and seepage into the surrounding soil.

To resolve this, the majority of channel (25 km) was drained, repaired and durable liner installed on top. The remaining 2.5 km+ of channel was replaced with underground pipelining in select areas where pipelining offered cost-efficiency and community benefits.

Works were broken into:

Channel lining

Mildura K&L channels

Use the white arrows on the image slider to see the before and after.

Red Cliffs channel

Use the white arrows on the image slider to see the before and after.

Merbein main channel

Use the white arrows on the image slider to see the before and after.

Pipeline installation

Mildura L Pipeline (‘Nichols Point Pipeline’)

The Mildura L Channel, which ran alongside the Nichols Point Primary School, posed a safety hazard due to its proximity to the community and the difficulty of climbing out if someone fell in. The project replaced the open channel with an underground pipeline, improving community safety and reconnecting the open space between the school and the oval.

Use the white arrows on the image slider to see the before and after.

Knife Edge pipeline, Merbein

Use the white arrows on the image slider to see the before and after.

The Ditch

Use the white arrows on the image slider to see the before and after.

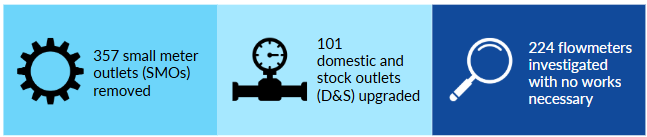

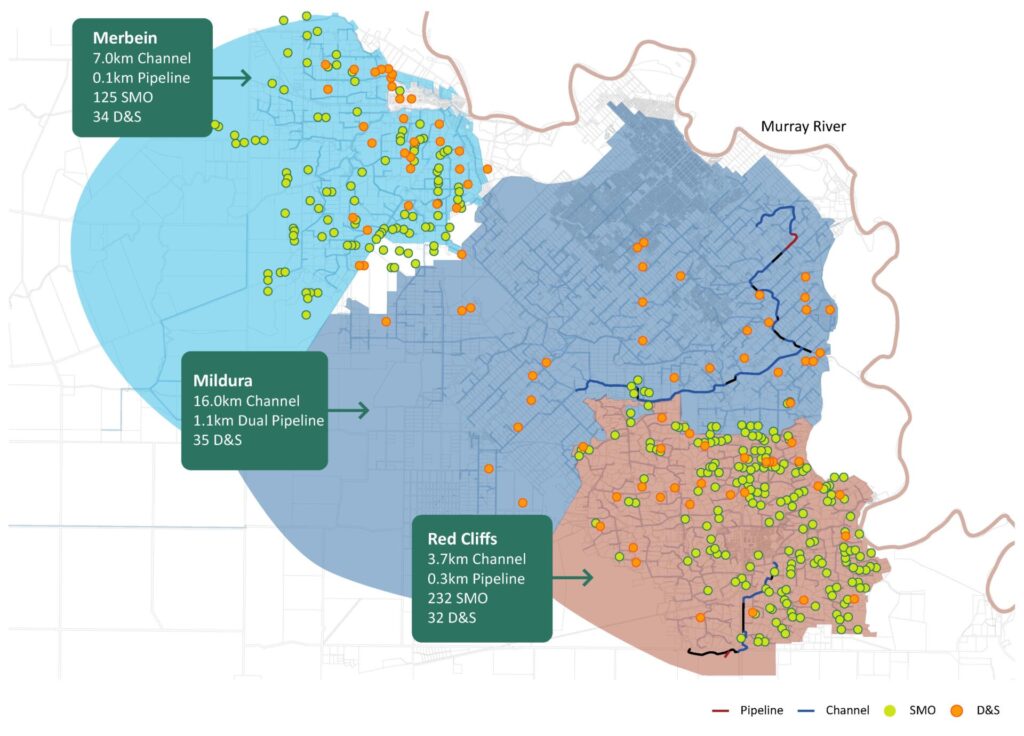

2. Meters

Redundant and inaccurate flowmeters contributed to water losses across Sunraysia’s irrigation network, due to leakage through or around the meters, as well as unauthorised use. As part of the project’s water recovery goals, the team replaced two types of meters across the network: small meter outlets (SMOs) which are also known as Dethridge wheels, and domestic and stock outlets (D&S).

Treating 682+ meters, comprising of SMO removals, D&S flowmeter upgrades, and investigations only:

Small Meter Outlets (SMOs) outlets

Before the project, 397 outdated Dethridge meters remained in LMW’s irrigation network. These meters, prone to inaccuracy and leaks, often caused water loss and even localised flooding.

The project team removed 357 of these meters, exceeding the Funding Agreement target and conserving water by eliminating system weak points.

Domestic and Stock (D&S) outlets

LMW uses Magflow and mechanical meters to measure domestic and stock water in its Red Cliffs, Mildura, and Merbein districts. Testing revealed some meters had errors of up to 100%, leading to unreported usage. The project identified and replaced faulty meters to improve measurement accuracy and reduce rural loss accounting.

Community engagement

Whether engaging with landowners, shut-down-impacted customers, industry or primary students in mini high-vis vests, it was clear the SWEP team had people at the heart of the project.

This genuine connection underscored our commitment to making SWEP more than just a project—it became a shared community experience. The project brought community along on the SWEP journey through educational tours, community events and even a community art initiative that turned removed water wheels intro art sculptures.

Mission accomplished: Project outcomes

Not only achieved within budget and on time, SWEP has also resulted in significantly more benefits for the Sunraysia community.

SWEP has been successful in all forms:

- An estimated $20 million regional GDP increase;

- Employment across Sunraysia increased, with 100+ local jobs created;

- The use of considered pipeline installation instead of channel relining has reduced safety hazards and opened up spaces and community and landowner access across the region;

- A community co-design project that has used removed Dethridge wheels and transformed them into sculptures across Sunraysia – giving the project a lasting presence in the region.

SWEP will support Sunraysia remaining competitive within Australia’s agribusiness sector.

With the project aiming to annually recover 1.8GL in water savings to be used for environmental purposes, the project has also made a significant contribution to preventing water scarcity and protecting the ecologically significant Murray Darling Basin.

Thank you

Thank you for to all growers, schools, contractors and community members who have played a part in making this project a resounding success.

Thanks also to the Australian and Victorian Governments for funding, supporting and believing in the Sunraysia Water Efficiency Project. Together, great things have been achieved.